Home > Listing Products > Gas Generators > Nitrogen Generators

Home > Listing Products > Gas Generators > Nitrogen Generators

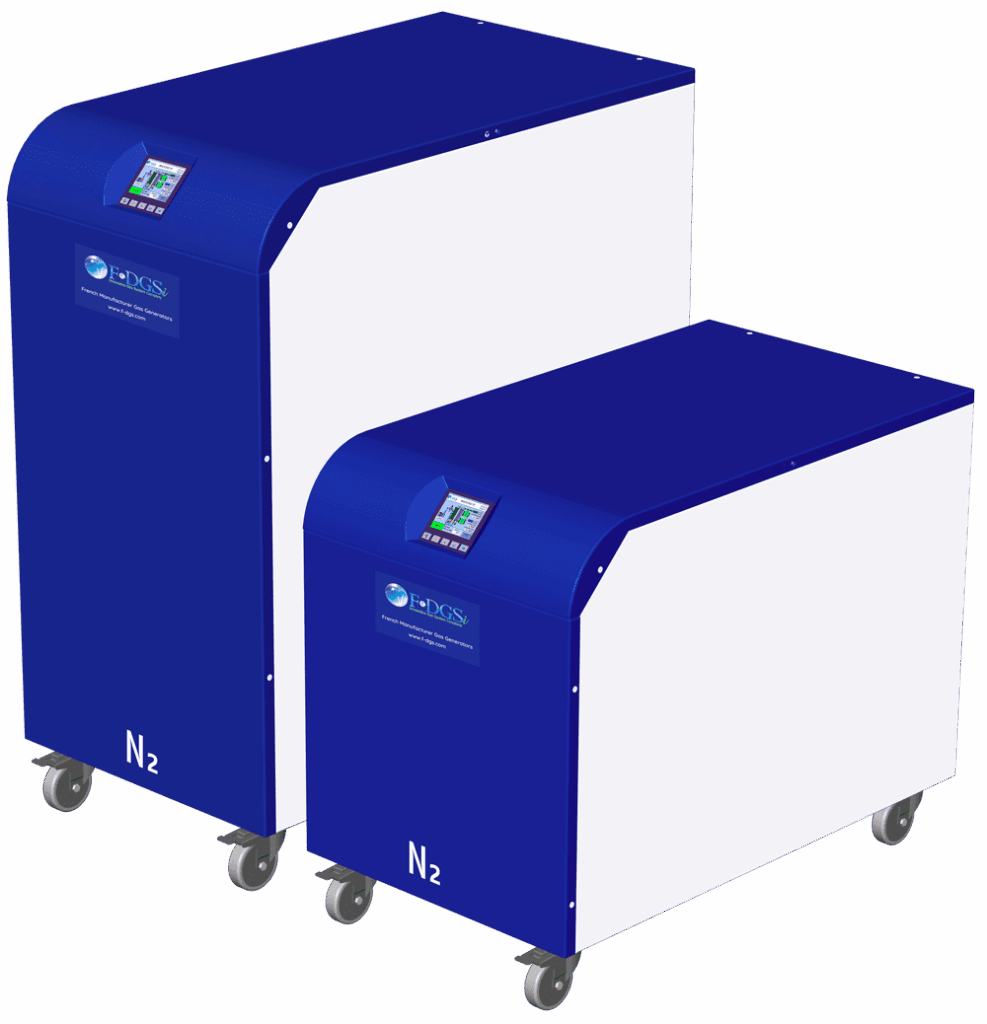

Need a high-quality nitrogen supply to guarantee reliable analytical results and optimize your LC-MS instruments? F-DGSi offers a comprehensive range of nitrogen generators suitable for a variety of analytical applications. From the laboratory (GC, LC-MS, CAD, ELSD, ….) to industry, our nitrogen generators are highly versatile.

Our first manufactured gas generator was a nitrogen generator feeding an LC-MS instrument. Our CALYPSO has become the benchmark for the world’s leading manufacturers of analytical instruments.

F-DGSi offers the widest range of nitrogen generators for laboratories, with flow rates from a few liters/min to several M3/H and purities from 95% to 99.9995%. F-DGSi generators produce nitrogen on site and on demand, providing an uninterrupted supply of high-purity gas to the application. There are two possible technologies for a nitrogen generator: membrane technology and PSA technology.

If you are interested in improving your laboratory nitrogen supply, contact us today or check out our wide range of nitrogen generators.

Nitrogen, a vital gas for many laboratory analytical applications, plays a central role in a variety of processes. F-DGSi stands out for its high-quality French nitrogen gas generators, widely adopted in laboratories around the world.

These generators are specially designed for a wide range of analytical applications, such as gas chromatography, liquid chromatography including LC-MS (Liquid Chromatography-Mass Spectrometry), sample evaporation and other industrial or semi-industrial uses.

Our range of laboratory nitrogen generators offers remarkable flexibility. Our N2 generators can produce pure nitrogen up to 99.9999%, with flow rates ranging from 500 cc/min to over 120 l/min. Gas generators ensure on-site and on-demand nitrogen production, guaranteeing a continuous supply of high-purity gas for your applications. Our CALYPSO generators are specially designed to fit most laboratory applications and equipment, as well as leading scientific instrument manufacturers such as Agilent, SCIEX, Shimadzu, Thermo, Leco, …

Gas generators offer an economical, reliable and environmentally-friendly alternative to traditional nitrogen storage and supply methods.

Nitrogen generators are a safer, more convenient alternative to using gas cylinders. Every time you change a gas cylinder, you run the risk of polluting your gas line with contaminants and impurities. Whereas with a nitrogen generator, once installed, it will always provide the correct, constant and worry-free gas purity to meet your needs. But how does a nitrogen generator work?

A nitrogen generator is a device used to produce nitrogen from ambient air. The air we breathe is composed mainly of nitrogen (around 78%), oxygen (around 21%), and traces of other gases. The nitrogen generator uses this principle to isolate and concentrate the nitrogen.

The nitrogen generator begins by drawing in ambient air and passing it through filters to clean it. It then compresses this filtered air to increase its pressure. After this comes the crucial step of gas separation. Two technologies are commonly used: membrane and PSA. We explain both technologies below.

Once the pure nitrogen has been separated from the other gases, it is used directly as required. The technology used generally depends on the degree of purity required for the nitrogen produced.

The gas generator is designed to absorb ambient air via an integrated air compressor. Pressurized air is first pre-filtered to remove water and dust from the atmospheric air. This pre-filtered air stream then passes through a CMS bed, also known as molecular carbon, which is in purification mode. Pressurized air passes through the CMS column so that O2, CO2, H2O and hydrocarbon molecules are retained in the molecular sieve. Nitrogen leaving the CMS column can be stored in a reservoir. During this CMS filtration phase, the second column is regenerated by depressurization supported by a nitrogen countercurrent. The process is cyclic and fully automatic, guaranteeing continuous production of clean, dry, high-purity nitrogen, with purities of over 99.999%.

Nitrogen generators using PSA technology achieve higher gas purity than membrane technology nitrogen generators.

What sets F-DGSi apart from its competitors is its PSA technology gas generators. This approach guarantees reliable production of pure gas, meeting the highest industry standards. Thanks to its commitment to innovation and quality customer service, F-DGSi maintains its reputation as a leader in the field of gas generators.

Nitrogen from the air is absorbed inside the generator. This air stream is compressed and pre-filtered to pass through a membrane made of semi-permeable polymer hollow fibers, enabling molecular separation. Small molecules such as O2 and carbon dioxide diffuse through the membrane pores, while the larger nitrogen remains in the membrane stream. The nitrogen gas is then set up and ready for delivery to the instrument. It’s still a simple system, but unfortunately, in addition to offering nitrogen with purities of less than 99.5%, it ensures a service life of less than 5 years, as there is no membrane regeneration. What’s more, to protect the membrane from hydrocarbons, we recommend adding an activated carbon filter.

The main consideration is the flow rate required. Membrane nitrogen gas generators can provide a stable source of nitrogen at various flow rates. However, if your laboratory requires a considerably higher flow rate while maintaining high levels of purity, a PSA nitrogen generator would be more appropriate to meet your laboratory’s specific needs.

We’re here to advise you in all cases, so please don’t hesitate to contact us for advice tailored to your specific needs.

There are several significant advantages to using a nitrogen generator. Firstly, nitrogen generators offer a safer and more convenient solution than using high-pressure nitrogen cylinders. They guarantee constant purity of the nitrogen produced, eliminating the risk of contamination that can occur when cylinders are replaced.

In addition, nitrogen generators are economically advantageous, reducing the costs associated with cylinder purchase, delivery and replacement. They also provide a continuous source of nitrogen on demand, eliminating potential interruptions to processes or experiments. What’s more, using a nitrogen generator is an environmentally-friendly option, reducing carbon footprints by avoiding frequent cylinder transport and ensuring more sustainable resource management in laboratories and industrial facilities.

For safe and efficient installation of a gas generator, choose an indoor location, next to your equipment or on a flat surface. Ensure adequate ventilation to prevent heat build-up. Our gas generators are distinguished by their discreet sound and compact size, ensuring perfect integration into your laboratory.