Home > Listing Products > Gas Generators > Hydrogen Generators > COSMOS MB.H2 Hydrogen Generator

Home > Listing Products > Gas Generators > Hydrogen Generators > COSMOS MB.H2 Hydrogen Generator

Standard Purity - Static membrane dryer

Reference

COSMOS.MB.H2.[Flow rate]

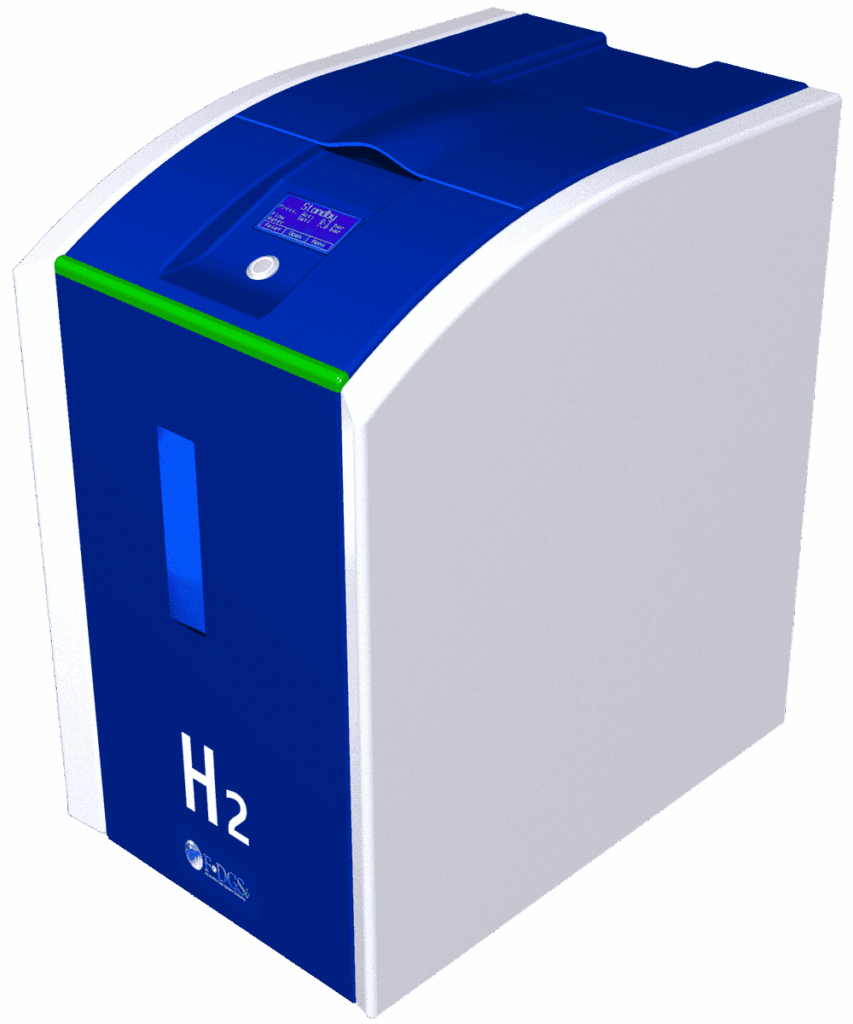

The COSMOS MB.H2 generator is designed for GC-detectors requiring H2 fuel gas such as FID, FPD, NPD and TCD.

The Hydrogen gas is produced from deionised water using the exclusive 100% titanium Proton Exchange Membrane (PEM) technology, which provides a very high reliability, new longer life and better purity.

The COSMOS MB.H2 series use a unique static membrane dryer, maintenance free, which allow to dry the H2 gas and increase the purity.

The automatic checking for internal leaks whenever starting the unit and constant control of operating parameters, guarantee maximum safety.

The touch screen interface provides simple and user-friendly management of all functions on the unit.

IMPROVED CHROMATOGRAPH RESULT

The use of hydrogen as a carrier gas allows lower temperature elution, thus extending the life of the chromatograph column. Hydrogen as a carrier gas is faster and more sensitive than the more-expensive helium. Run time savings of 25% to 35% without a decline in resolution.

INCREASED LABORATORY EFFICIENCY

A constant, uninterrupted gas supply of guaranteed purity eliminates interruptions of analyses to change cylinders and reduces the amount of instrument re-calibrations required.

The very limited internal volume (less than 50 ml) allows safe use of the gas generators where the use of cylinders is risky or prohibited.

The application of tested safety technologies stops the unit in the event of leaks or malfunctions

Gas generators can be installed in the laboratory, on or under a bench, eliminating the need for long gas lines from cylinders secured elsewhere.

Models | MB.H2.110 | MB.H2.170 | MB.H2.260 | MB.H2.300 | MB.H2.400 | MB.H2.500 | MB.H2.600 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

GENERALS INFORMATIONS | |||||||||||

H2 flow rate -cc/min | 110 | 170 | 260 | 300 | 400 | 500 | 600 | ||||

Electrolytic cell | Long life Multilayer PEM technology | ||||||||||

H2 purity | > 99.9996 % (O2 < 1 ppm, Dew Point< -20°C (-4°F)) | > 99.9996 % (O2 < 1 ppm, Dew Point< -30°C (-22°F)) | |||||||||

Delivery pressure | 1 – 7 bar (14 – 101.5 psi) | 1 – 11 bar (14 – 160 psi) | |||||||||

H2 dryer | Static membrane dryer, maintenance free | ||||||||||

Temperature range | From 5 – 35°C (41 – 95°F) and humidity 80% to 25°C (77°F) | ||||||||||

Touch screen | Touch screen (operating parameters, system status, alarms) with LED indicators (Power on/off; ready or errors) | ||||||||||

Dimensions(W x H x D) | 27 x 44 x 38 cm (10.5″ x 17″ x 15″) | ||||||||||

Weight (kg/lbs) | 18 / 39 | 19 / 42 | |||||||||

Power consumption | 75 W | 95 W | 140 W | 180 W | 190 W | 230 W | |||||

Electrical supply | 220 – 240 V 50 Hz | ||||||||||

110 – 120 V 60 Hz | |||||||||||

WATER | |||||||||||

Water quality | Deionised, ASTM II, < 0.1 μS Conductivity | ||||||||||

Supply pressure | Max. 6 bar | ||||||||||

Internal water tank | 2.3 liters | ||||||||||

External water tank capacity (Optionnal) | 5 or 10 liters | ||||||||||

CONNECTIONS | |||||||||||

Hydrogen outlet | 1/8 Swagelock | ||||||||||

Water inlet | Quick release push-in fitting | ||||||||||

COMMUNICATION | |||||||||||

USB/PC Control | N /A | In series | |||||||||

RS232/RS485 | N /A | Option | |||||||||

ACCESSORIES | Water tank 5 liters | Water tank 10 liters |

|---|---|---|

Part Number | water.tank.005 | water.tank.006 |

Having all the necessary information to successfully complete your project is essential, which is why we are providing you with these documents.

Please feel free to contact us with any questions.